PRANAV AUNDHKAR

Product Development Engineer III

April 2020 - April 2023

Airmaster Fan Company

Clarklake, MI

My contributions to this role and team revolved around my strong project management skills, expertise in CAD-CAM, product innovation, and design and development capacities. I have hands-on experience with product design and development systems, as well as major manufacturing and quality engineering tools. My main focus has been on optimizing current products and processes, and developing innovative solutions to improve product functionality. I have worked on successful product launches and multiple custom-tailored projects.r Airmaster Fan Company that have proven high ROI for the organization.

Awarded as an 'Employee of the year' in the year 2020 for my excellent contributions to product development.

AWARDS

COMPANY

Airmaster Fan Company is a manufacturer and suppliers of complete air circulation, ventilation and heating solutions. Airmaster Fan designs and develops its products in-house owing to its strong engineering support.

Airmaster Fan is owned by MAICO group-Germany, a globally recognized leader in ventilation products. Airmaster fan exports throughout the world and offers largest line of air moving equipment. Airmaster Fan works collaboratively with its subsidiaries in Germany, Italy, UK, Gulf, China and India to develop niche products for global markets.

SKILLS

INDUSTRIAL MISTING FAN

• Project manager- product development and launch.

• CAD Modelling - Solid works 2020.

• Material, parts and hardware selection.

• Tooling design - Roll forming.

• CNC Machining Coding for sheet metal parts.

• Selection of fabrication processes and mapping manufacturing process flow for assembly.

• Setting up pilot production assembly line along with APQP.

• Develop & Maintain QMS.

• Coordinating to establish UL/ETL testing and certification standards.

• Estimated Annual Sales of 400+ units: USD 450k in Revenue per year.

• 100% Made and Assembled in the USA.

AIR DIFFUSER V-FLO FAN (GREENHOUSE APPLICATIONS):

• Project manager - Product innovation, development and launch.

• CAD Modelling - Solid works 2022.

• CFD Analysis for performance measurement.

• Material, parts and hardware selection.

• Selection of fabrication processes and mapping manufacturing process flow for assembly.

• Coordinating to establish BESS labs testing and certification standards.

• Highest Thrust Efficiency (CFM/Power) - 28.70%, making it strongest of all its competitors.

• Estimated Annual Sales of 150+ units: USD 200k in Revenue per year.

• 100% Made and Assembled in the USA.

30" VFLO

CFD Study: Velocity Vol. Rendering

INTERACTIVE INSTALLATION INSTRUCTIONS - I3

• Conceptualizing and leading the development of I3s for customer ease.

• Helps with better understanding of installation procedure and requirements.

• Develop designs for all complex assemblies' and configurations.

I3 Demo

OTHER PROJECTS

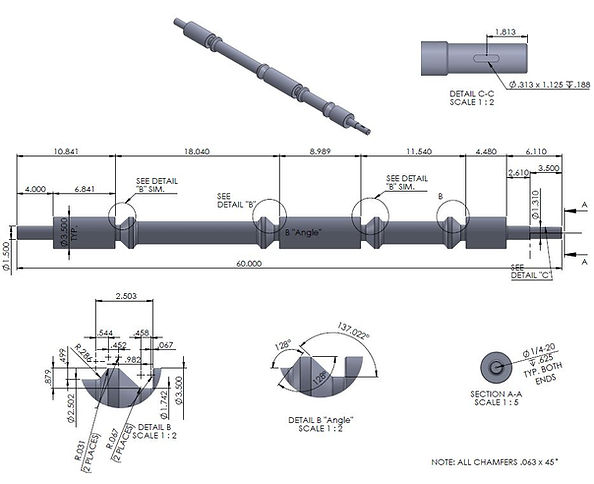

1. TOOLING DESIGNS & DEVELOPMENT

Tooling Design

Detailed Layout - Engineering Drawing

2. CUSTOM PANEL FAN

From customer request to initial prototype, tooling design and pilot production part in 2 days – Project Planning & Execution in cross functional environment.

28" Fan Panel

3. AGRIC PANEL FAN - 48"BARN FAN

48" Barn Fan

4. INDUSTRIAL BLOWER

ARD Series Blower

5. AIR CIRCULATOR (HEAD ASSEMBLY)

HD Series - 30" Air Circulator

ROLE AND RESPONSIBILITIES

-

Lead and manage the Engineering Department - team of 4 along with R&D activities.

-

Responsible for resource management (team development, coaching) and project escalation.

-

Utilize SolidWorks & AutoCAD 3D/2D modelling to develop complex product assembly, tooling, and fixture designs.

-

Conduct research to create concepts, design proposals, performance criteria and production plans for the products.

-

Lead and maintain DFMEAs, DVP&Rs with other quality documentation.

-

Create Engineering Road Maps for upcoming projects and plan for new product developments.

-

Define capital equipment and tooling required and maintain adherence to the budget of the project.

-

Conduct time studies and track process changes to highlight impacts to the product cost, quality, and delivery.

-

Lead the development of the process flow including assembly equipment, quality checks, work instructions, control plans, end-of-line (EOL) testing, functional/durability testing as required.

-

Work in cross-functional environment to ensure projects are properly resourced with respect to marketing, sales, procurement, and manufacturing support and involvement.

-

Multi stakeholder alignment - partners with Service, R&D, Global Operations, Quality, Marketing and Sales to develop new products & projects. (MAICO - North America, Europe, Gulf & China).

-

Hands on with metal fabrication, injection molding, packaging designs, and motor-driven mechanism development.

-

Perform and manage all other tasks as delegated by senior management.